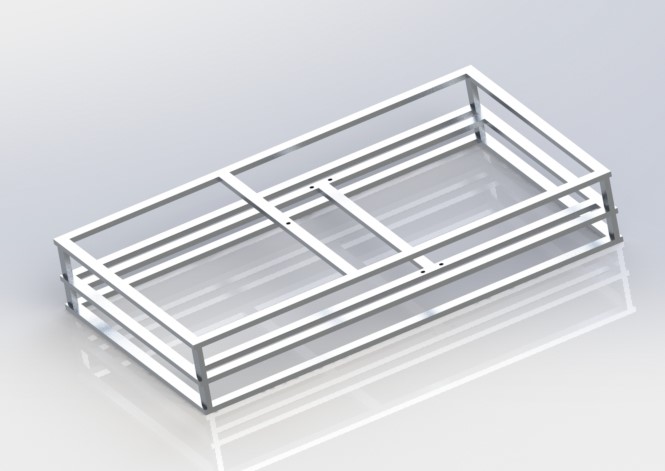

The chassis frame is made of aluminium box section profiles, brazed together to form a sturdy and lightweight frame.

All the components are placed in a manner to bring the centre of gravity towards the centre of the rover and to ensure proper balance for the rocker bogie mechanism. Also the chassis is built in such a way that the centre of gravity of the rover is lowered.

The chassis consists of two different compartments, one to hold the manipulator and the other for all the different electronic components.

Also the chassis is built keeping in mind space for the soil collecting mechanism.

We have built an Articulated arm with 6 degree of freedom and a 3D printed parallel gripper end effector. Opening and closing mechanism of Gripping fingers is performed by rotating the link about a fixed axis using a lead screw.

We have made use of 6 revolute joints being operated with the help of pulleys in order to keep the motors at the base of the assembly. We have also made use of a bevel gear system in order to help the manipulator lift more weight.

The gripper was 3D printed for a lightweight construction that can withstand high transverse and shearing stresses.

The rover is configured to a 6 wheel rocker bogie mechanism.

It also makes use of a differential bar which is attached to the chassis and helps in providing stability to it. The rocker in the rocker bogie is not restricted by any other force and hence it can help in maximum ground contact.

The rocker bogie with differential also helps in maximising the obstacle climbing capabilities and also avoids toppling.

For the end effector we have used a parallel gripping mechanism with 3D printed gripper.

The opening and closing of the gripper is done with the help of a mechanism similar to a parallel four bar with the motion done with the help of a lead screw.

The end effector is fixed to a bevel gear system which rotates the gripper about its axis and also along an axis perpendicular to the first axis.

The wheel is manufactured in such a way that it can provide traction to the rocker-bogie system

The zig-zag pattern on the wheel can provide enough traction on grassy terrain and ensure the rover can travel over slopes without slipping. Surface layer of the wheel is made out of rubber.

Its large diameter gives it an advantage when it comes to protecting Rover's base from damage.

A star like structure is used to couple the motor with the wheel. The motor will be placed in an aluminium pipe which is connected to the rocker bogie mechanism.