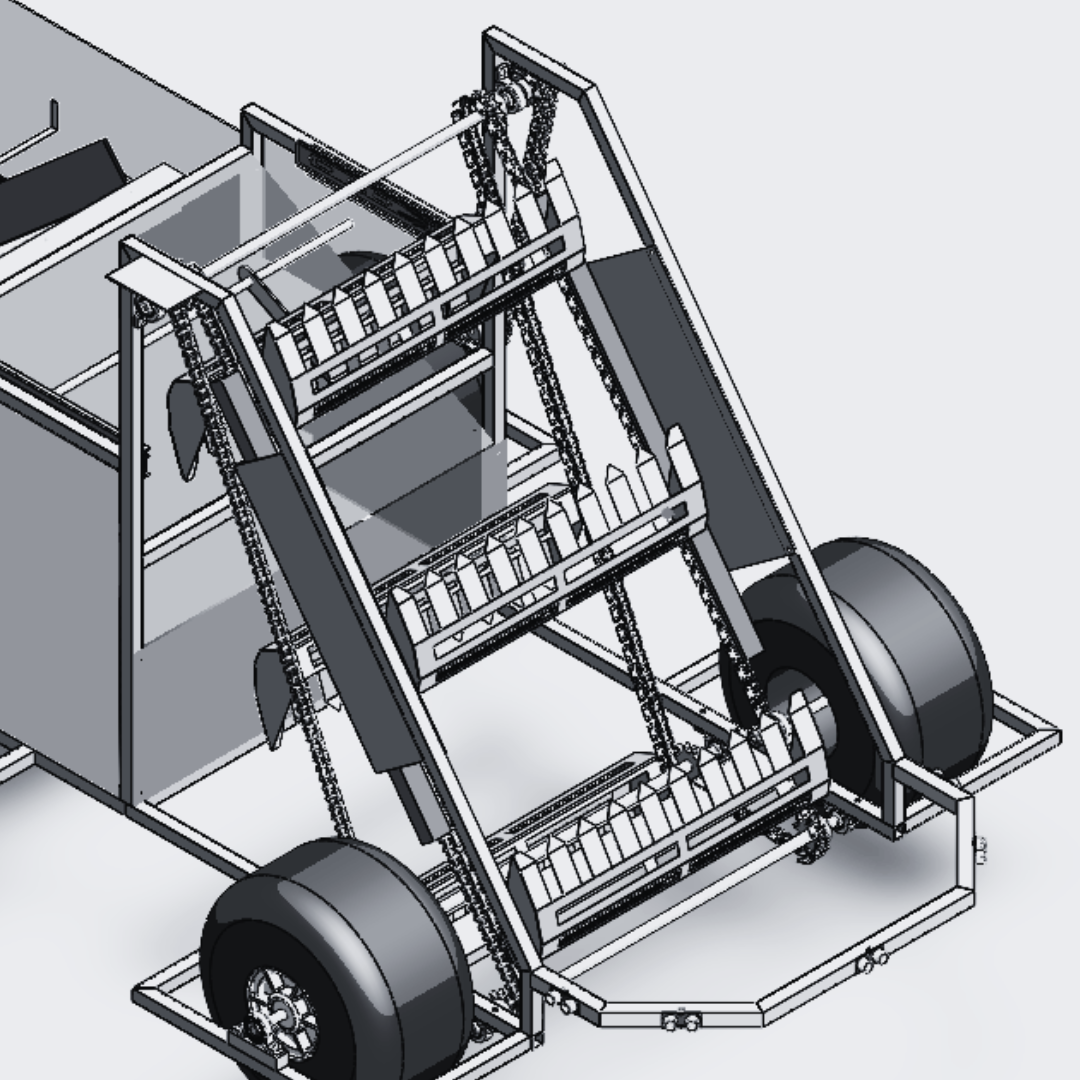

A clawed conveyor system is provided to efficiently collect the waste.This mechanism consists of a long loop of chain,supported by chain guides to ensure proper stability of the system.

K2 attachments are installed over the chain at specific distances and precisely designed claws are attached to the system.

This configuration enables the claw attachment to seamlessly rotate with the chain,effectively digging 20-30 mm into the ground to gather waste materials.

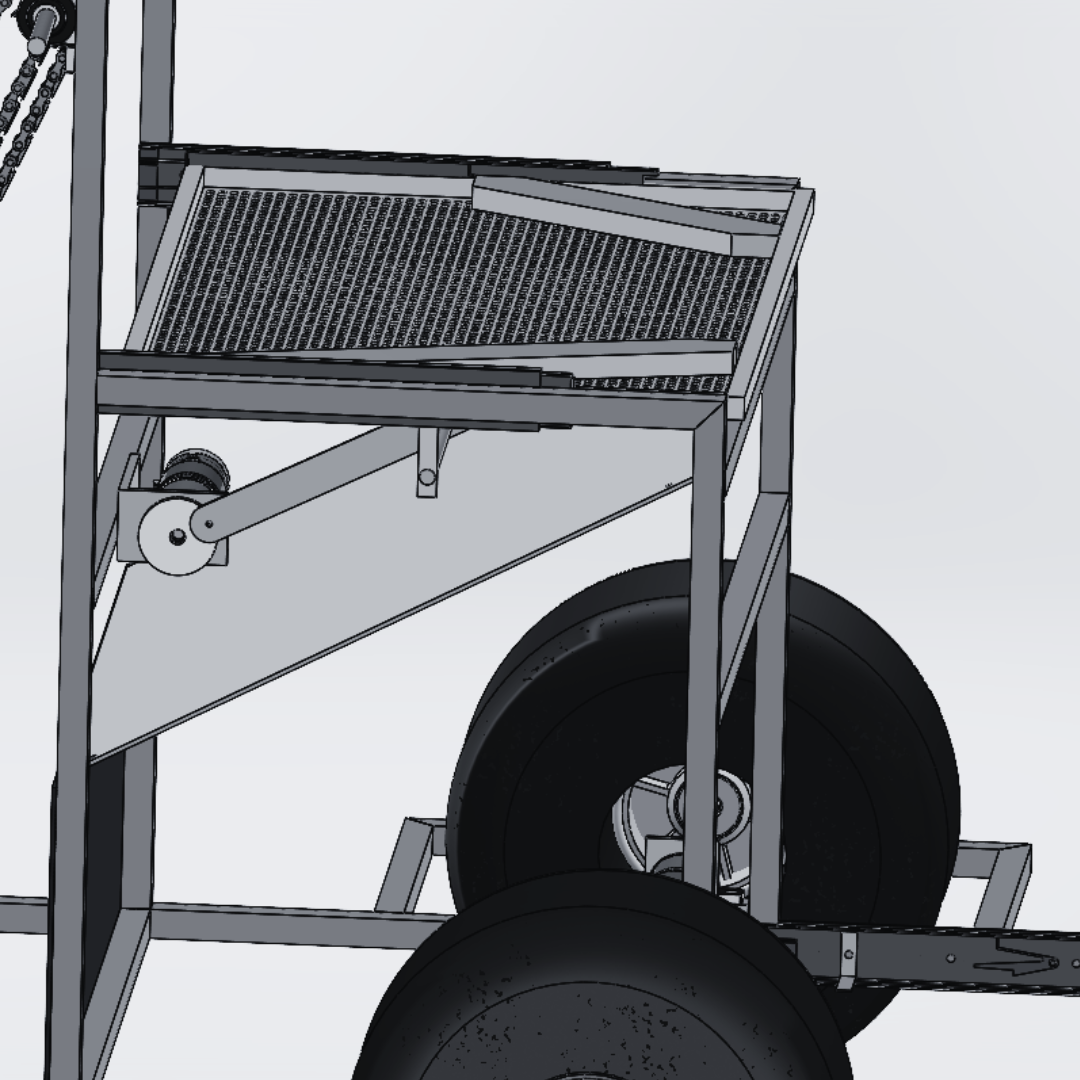

The slider-crank mechanism, a widely employed mechanical linkage, serves the purpose of converting rotational motion into linear motion or vice versa.

Once the waste is collected, it is transferred onto a vibrating screen propelled by the slider-crank mechanism. This mechanism's function is to generate mechanical vibrations, facilitating the separation of loose beach sand from the waste material.

The vibrating screen induces movements that cause the sand particles to detach from the waste due to applied mechanical forces.

Simultaneously, these vibrations play a crucial role in transporting the separated waste to the detection panel.

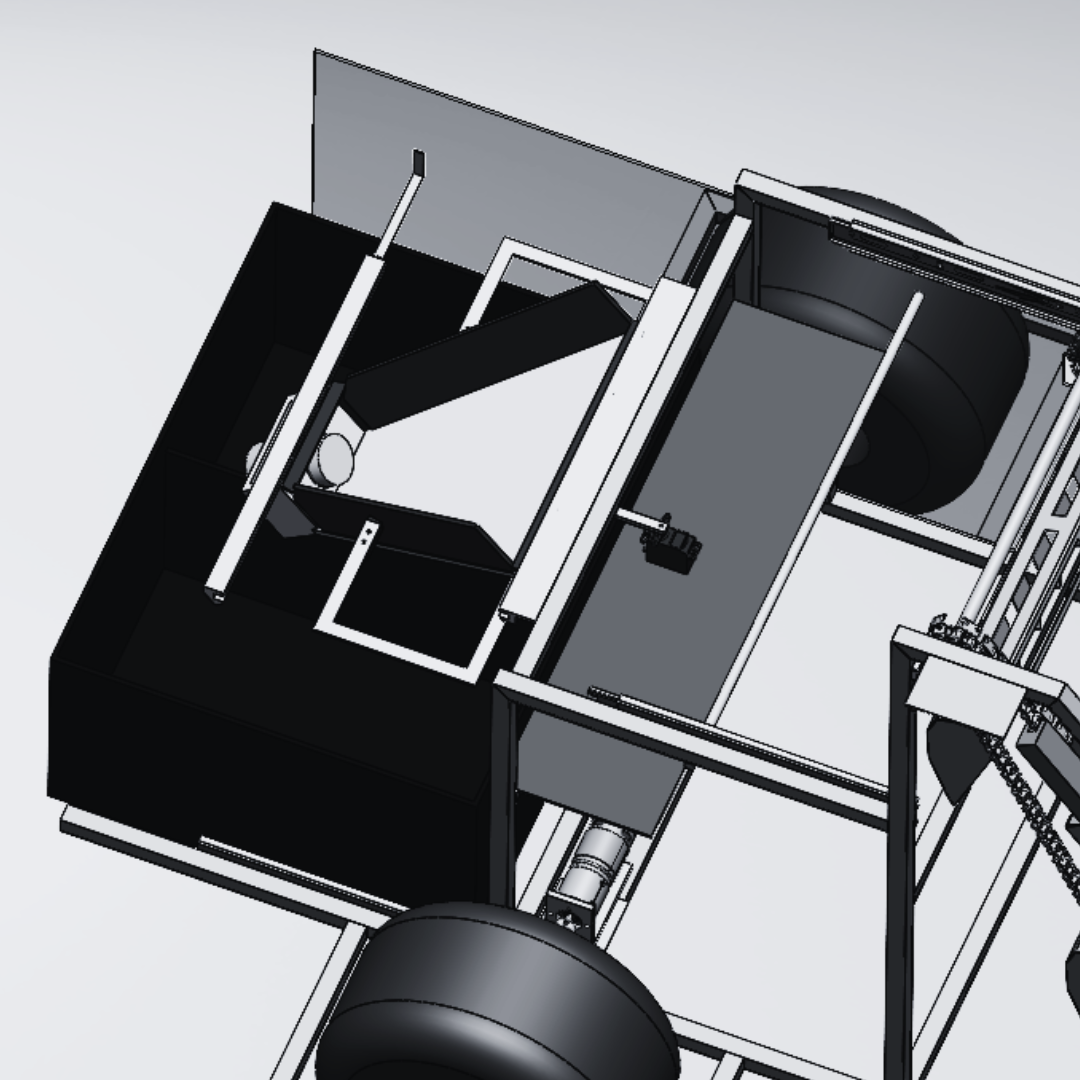

To channel waste effectively towards the sensor, a system was integrated into the vibrating sieve. Two guides, strategically positioned with an offset, ensure that the distance between them exceeds the size of the largest targeted waste object. This configuration prompts the waste to converge and align vertically before entering the segregation module.

The segregation module consists of 2 component:

Base: This component incorporates a resting plate designed for waste detection, guides for the flap at the extremities, and a mount for the capacitive sensor.

Flap: The flap component is equipped with extrusions featuring press-fitted bearings, facilitating smooth movement within the guides of the base. The flap's role is to push the waste into designated bins, and this motion is controlled by a servo motor. The linear reciprocating movement is achieved through a four-bar mechanism.